Patent MarketPlace: Manufacturing

Next-Generation Copper Electrowinning (Pueo): U.S. Patent Application 20250198030 and EPO Application 4497852

Next-Generation Copper Electrowinning (Pueo): U.S. Patent Application 20250198030 and EPO Application 4497852

Copper is a critical enabling material for energy transition and other advanced technologies. Renewables and grid expansion, modern defense systems, electric vehicles, and AI/data-center infrastructure all depend on copper. As demand rises, SX–EW (solvent extraction-electrowinning) operators are under pressure to get more production from existing tankhouses. Any sustainable increase in operating current density translates directly into more tons of copper per year – and that is exactly what these patent applications address.

This patent family introduces an electronic intercell switching system that replaces passive intercell insulators in SX–EW tankhouses with intelligent electronic insulators. Intrinsic reverse pulsing suppresses dendrite formation and raises the practical operating current-density ceiling of industrial EW cells, while maintaining or even improving cathode quality. It also enables safe industrial operation of titanium MMO/DSA (mixed metal oxide / dimensionally stable anodes) in copper EW cells, overcoming the severe dendrite-related issues that have historically limited their use. In practical terms, it enables existing electrowinning plants to produce more copper from the same footprint, without building new tankhouses or installing external pulse power systems.

U.S. Patent Application 20250198030 and European Patent Application 4497852 for an “Electrowinning system with interconnectable intercell bars” would be a strategic acquisition for any operator of large SX–EW tankhouses, or for businesses that supply EW/SX tankhouse technology, rectifiers or MMO/DSA anodes, and want to embed intrinsic reverse pulsing into their product portfolio.

Improved Fan Balancing (Eichler): U.S. Patent No. 12,270,418

Improved Fan Balancing (Eichler): U.S. Patent No. 12,270,418

Fans are everywhere: Heating, air conditioning, and refrigeration units; ceiling and exhaust fans for homes, schools, and factories; power plants; air handling for shopping centers, hospitals, and office buildings – the list goes on and on. And the blades on each of those fans need to be balanced so the fan will rotate smoothly with minimal vibration. A pretty big task.

This patent takes on that task. It consists of a sensing device that attaches to a fan to collect vibration and rotation data plus a remote device that wirelessly processes this data to determine precise weight placement locations for balancing the fan. This patented technology eliminates the traditional trial-and-error approach to balancing the blades on a fan, reducing the time required to balance a fan from an hour-and-half or more to just a few minutes. And the technology balances the fan more accurately, improving the performance and extending the life of the fan. This technology is proven since it is a variation on how tire dealers balance tires after mounting them on rims.

U.S. Patent No. 12,270,418 for “Remote field fan balancing system” would enable any industrial fan manufacturer to offer a product for its customer base – and the customer base of all of its competitors – that will help them keep all their fans balanced and operating at peak performance.

Improved Productivity Chuck Adaptor (Davidian): U.S. Patent Application 20220379388

Improved Productivity Chuck Adaptor (Davidian): U.S. Patent Application 20220379388

Lathe and CNC milling has been used to produce parts for over a century, and hydraulic chucks are a critical component in this manufacturing sector. Standard chucks for lathes and milling machines range from 8 to 12 inches in diameter and weigh from 50 to 120 pounds, and they are made from a hard alloy steel. To use these chucks, there are three or four jaws that hold the stock material. These jaws themselves must be machined in order to fit different diameters, and this process requires expertise, time, and resources. A collet holder must be installed on the shaft of the chuck to hold smaller diameter metal stock.

The "Rapid Change Chuck Adaptor" created by this patent enables lathe and milling operators to manufacture various diameters of stock without having to remove chucks and machine multiple jaws. This patent filing completely re-thinks the chuck concept. Once a chuck based on this filing is installed, collets can be used immediately. Once it is removed, the worker can immediately utilize jaws on the chuck. The chuck remains on the machine, and collets can be used for smaller diameters. For large diameter material, the device is removed in a matter of seconds! A chuck adaptor based on this patent provides twice the versatility of a conventional chuck adaptor in a fraction of the time – even for unskilled or untrained operators! A device based on this invention would weigh just 12 pounds. At just one-fifth of the weight of a conventional chuck adaptor, and 30 times faster, this invention would improve efficiencies by a factor of 150! The savings on downtime, reductions in workplace incidents from heavy lifting, and the ability to maintain true length tolerance, make this invention revolutionary!

U.S. Patent Application 20220379388 for a “Rapid change chuck adapter” would enable any manufacturer of lathe or CNC tooling to introduce a next-generation chuck adaptor that will dramatically save time and money, and substantially improve productivity, for its customers.

AI-Powered Product and Food Testing (BriteScan): International Patent Portfolio

AI-Powered Product and Food Testing (BriteScan): International Patent Portfolio

Many of the foods we consume and products we purchase are not adequately tested for quality, safety, or purity due to the high costs, lengthy turnaround times, and unreliable testing methods traditionally used. This issue is compounded by the rising threat of fraud, fueled in part by global supply chain disruptions and shortages. It is estimated that over 10% of foods, 30% of fish, and 50% of herbal products contain unlabeled or substituted ingredients which can pose serious risks to consumers. To protect both consumers and their reputations, and to comply with regulations, businesses across all industries need a more efficient way to test both raw materials and finished products. Faster, more affordable, and more accurate testing methods are essential to ensuring product quality and safety in today's marketplace.

This international patent portfolio covers the foundation for the next generation of testing technology, leveraging the power of Artificial Intelligence (AI) through image analysis with Computer Vision (CV) and Machine Learning (ML). It encompasses a broad range of testing device configurations designed to overcome the limitations of traditional testing methods by creating simple, yet highly functional and accurate devices that can be used by anyone—regardless of expertise. These devices enable instant testing of a wide range of materials including solids, powders, and liquids, as well as both biological (plants, animals, meat, fish, human samples, etc.) and non-biological substances. This includes natural materials such as gems, diamonds, and soil, as well as manufactured goods like food, cosmetics, collectibles, and luxury goods.

Devices developed from this portfolio are scalable to accommodate different material types and sizes, from small, handheld units that can be passed over items to larger devices, stationary systems, or even integration into smart appliances like refrigerators and ovens. The technology combines still image and/or video capture – either through built-in hardware or external smartphones, cameras, and computers – with cloud-based AI software to process and analyze the data. These devices can inspect individual items, batches, or a continuous streams of items moving along assembly lines or conveyors, offering unprecedented speed, accuracy, and accessibility in testing.

This technology enables the creation of a comprehensive testing and verification system. It ensures that the correct raw materials are used, components are properly assembled and packaged, and the final product meets quality standards and regulatory requirements. The system can be employed for critical testing, accurately detecting inconsistencies or impurities in processed materials, ensuring compliance with manufacturing regulations, and maintaining product consistency. The device can be operated via a touchscreen, controlled remotely through Bluetooth, or integrated into a smart factory, smart building, or smart home system for seamless automation and monitoring.

Patent Portfolio

- U.S. Patent No. 10,684,231: Portable scanning device for ascertaining attributes of sample materials

- U.S. Patent No. 11,054,370: Scanning devices for ascertaining attributes of tangible objects

- U.S. Patent No. 11,243,172: Portable scanning device for ascertaining attributes of sample materials

- U.S. Patent No. 11,054,370: Scanning devices for ascertaining attributes of tangible objects

- U.S. Patent No. 12,007,332: Portable scanning device for ascertaining attributes of sample materials

- China Patent Application 11288893: Portable scanning device for ascertaining attributes of sample materials

- European Patent 3833242: Portable scanning device for ascertaining attributes of sample materials

- European Patent Application 4321862: Portable scanning device for ascertaining attributes of sample materials

- Canada Patent Application 3108903: Portable scanning device for ascertaining attributes of sample materials

- Switzerland Patent 3833242: Portable scanning device for ascertaining attributes of sample materials

- Spain Patent 2972637T3: Portable scanning device for ascertaining attributes of sample materials

- UK Patent 3833242: Portable scanning device for ascertaining attributes of sample materials

- Ireland Patent 3833242: Portable scanning device for ascertaining attributes of sample materials

- India Patent 521960: Portable scanning device for ascertaining attributes of sample materials

- Unitary Patent 3833242: Portable scanning device for ascertaining attributes of sample materials

This portfolio offers equipment manufacturers or technology companies the opportunity to own and control the next generation of inspection technology. It introduces a scalable, user-friendly, affordable, durable, and adaptable device that provides reliable test results instantly on-site with cloud-based results accessible in real time anywhere in the world.

Picklex® 20 Transformative Metal Treatment (International Chemical): Trade Secret and Trademark

Picklex® 20 Transformative Metal Treatment (International Chemical): Trade Secret and Trademark

Metals are used in all kinds of industries, but metals have rust and rust protection problems that require them to go through rigorous metal surface preparation before they can be finished to meet today’s quality requirements. Cleaning with solvents, grinding before welding, and blasting before painting or powder coating produces hazardous waste. Additionally, acids, phosphates, and chromates are hazardous, toxic chemicals that create waste disposal and environmental problems.

Picklex® 20 is an environmentally safe, non-hazardous, value-added metal preparation treatment. It performs complete metal surface preparation and pre-treatment in one step in one minute or less without heating or rinsing. It totally replaces the hazardous and toxic chemicals that are currently in use, and it eliminates the need for grinding or blasting to prepare metal surfaces for painting or powder coating.

Picklex® 20 can be used for the following applications in one step:

- Rust removal and indoor rust protection (8 to 10 years or longer)

- 100% rust conversion (converts mill scale/pitted rust to a weldable/paintable condition)

- Welding preparation

- One-step liquid painting preparation

- One-step powder coating preparation

- One-step de-rusting/de-scaling/pickling/coating

- Replaces chromate conversion coating and wash primer with chromate

- Stainless steel passivation (replaces nitric acid passivation)

Picklex® 20 has been on the market since 1998. It has no competition, a loyal customer base, and an excellent reputation. The owner of Picklex® 20 is making the formula for the product and the product’s trademark available for licensing for the first time. This is an opportunity for any producer of industrial chemicals to add a new product to its lineup that has a 25-plus year reputation and a multi-industry following.

Picklex is a registered trademark of International Chemical Products, Inc.

Lower-Cost Low-Density Polyester Foam (WRH Technology): International Patent Portfolio

Lower-Cost Low-Density Polyester Foam (WRH Technology): International Patent Portfolio

Low-density polyester foam has become very popular for both synthetic lumber and packaging. When made into sheets or boards, it can be sawed, planed, drilled, and fastened with screws. It performs just like a wood, but it will not warp, mold, or rot. And it can be priced to be competitive with construction-grade wood products such as plywood, making it an excellent green construction alternative. When used as packaging, low-density polyester foam can be priced close to the cost of polystyrene and cheaper than other resins. However, low-density polyester is made from recycled plastic bottles, so it is greener than polystyrene and other petroleum-based packaging.

The appeal of low-density polyester foam would be greatly enhanced if the cost of manufacturing it could be significantly reduced, and that is what this portfolio does. It reduces the cost of low-density polyester foam that is made from post-consumer recycled bottle flake and virgin polyester resin. Bottle flake can make up to 100% of the polymer in this patented formulation and is the preferred raw material. Using this technology, the low intrinsic viscosity of the raw material is increased to 1.1 dl/g (deciliters per gram) or greater to create a polyester resin that can be foamed to a specific gravity of less than 0.65 g/cc (gram per cubic centimeter) with typical products having a specific gravity of 0.2 to 0.4 g/cc.

Patent Portfolio

- U.S. Patent No. 11,111,350: Method for production of low density polyester foam and articles made thereof utilizing low I.V. polyester feedstock

- European Patent Application 3707197: Method for production of low density polyester foam and articles made thereof utilizing low i.v. polyester feedstock

- China Patent Application 111356726: Method for producing low density polyester foam from low intrinsic viscosity polyester feedstock and articles made therefrom

- Canada Patent Application 3071565: Method for production of low density polyester foam and articles made thereof utilizing low i.v. polyester feedstock

- Brazil Patent Application 112020003876: Method for producing low density polyester foam and articles thereof using a low i.v.

- Mexico Patent Application 2020004089: Method for production of low density polyester foam and articles made thereof utilizing low i.v. polyester feedstock

This portfolio would enable any polyester manufacturer to dramatically lower manufacturing costs for the low-density polyester foam it produces and sells!

Removal of Oil from Waste Water (Hylla): Two U.S. Patents

Removal of Oil from Waste Water (Hylla): Two U.S. Patents

We’ve been drinking and washing ourselves in the same recycled water for hundreds of years. Waste water goes down our drains and into the municipal sewer system along with rain and melted snow. The water is treated by the local water authority and retuned to us to drink and to wash ourselves, our dishes, our floors, our pets, and our cars. Getting solids out of the water is done via filtration, and bacteria and other contaminants are treated chemically.

Industrial facilities such as refineries and chemical plants face the challenge of removing oil from their waste water before it goes into the public waste stream and ends up as drinking water. Filtration will not remove oil from the waste water stream; a more sophisticated technology is needed. This patent family addresses that challenge be creating a combination mechanical and chemical process that uses agitation of the water, oil, and solids mix as well as treatment of the mix with a diluent, a solvent additive, and a detergent salt so the oil can be efficiently and effectively removed from the waste water.

U.S. Patent No. 8,999,148 for “Systems and methods for waste oil recovery” and U.S. Patent No. 9,815,711 for a “Systems for waste oil recovery” will enable a manufacturer of waste water treatment equipment to provide refineries, chemical plants, and other industrial facilities with an efficient system for removing oil from their waste water streams.

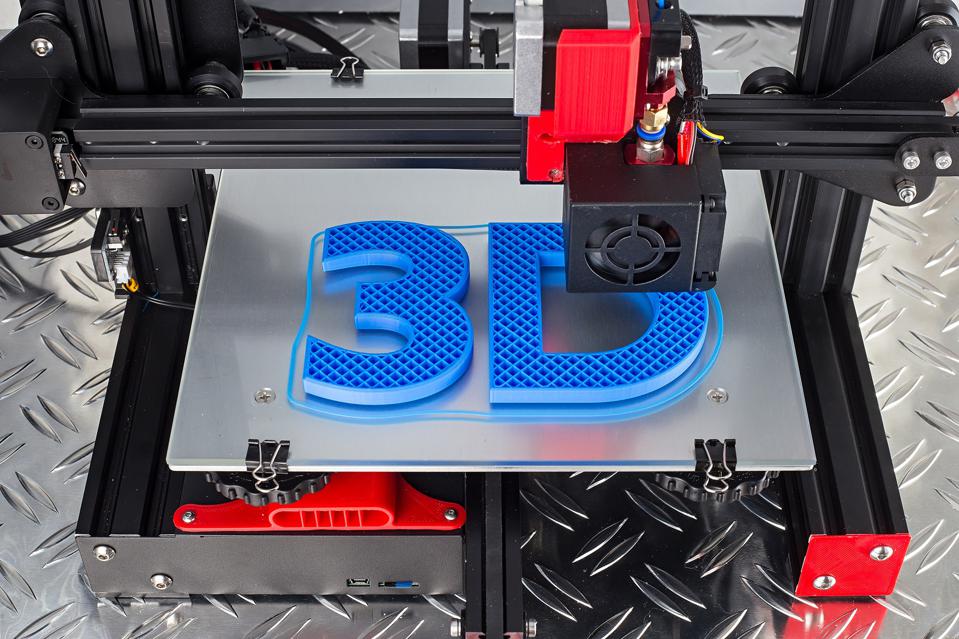

Next-Generation 3D Printing (Temirbulatov): U.S. and Chinese Patents

Next-Generation 3D Printing (Temirbulatov): U.S. and Chinese Patents

3D printing has been around since 1984 and has grown to a $12 billion global industry! 3D printing (also known as “stereolithography”) is the process of creating a 3D (height, width, and depth) object layer by layer. A head passes back and forth (like the head on a printer), laying down coating after coating of material to create the object. The process is, of course, slow, but it is ideal for creating a one-off sample or prototype. And while the technology is cutting edge, it has limitations. With just a few exceptions, 3D printers are limited to using plastic to create objects – most commonly Acrylonitrile Butadiene Styrene (or “ABS”) and Polyethylene Terephthalate Glycol (or “PETG”) – and that limits the strength, durability, and applications of 3D-printed objects.

This family of patents takes 3D printing to a new level of productivity by creating a modified extrusion pattern for the working material. A rotary piston extruder for a 3D printer head preheats polymers to a liquid form for extrusion of the working material. This enables printing at higher temperatures, and that increases adhesion, ensuring more accurate and precise extrusion of the material resulting in higher productivity and the ability to work with various polymers. The working material can be fed into the printer as either a thread or as granules.

During the operation of the extruder, the molten working material is sucked into the upper portion while it is extruded out from the lower part, providing a continuous supply of material to the construction surface. Since the working chamber is sealed, the extruder is able to work with various materials from liquid to paste such as ceramic, silicone, rubber, and two-component resins, as well as various melted metals. This patented rotary extruder significantly reduces both the cost of printing and the cost of equipment ownership.

U.S. Patent No. 11,285,666 and Chinese Patent 213055924 for a “Rotary piston extruder head for 3D printer” would be a strategic acquisition for any 3D printer manufacturer, and would enable the company to dramatically expand the materials that its 3D printers can use to create objects, dramatically expanding their applications and market appeal.

Patent Brokerage Prospectus: Contact [email protected] to receive an analysis of each portfolio that includes:

- Executive Summary

- Patent Overview and History

- Technology and Investment Summary

- Market Research

- Company Analysis

- Illustrative Evidence of Use (if applicable)

We offer patents in these technologies:

- Agricultural

- Artificial Intelligence

- Automotive/Vehicular

- Aviation

- Banking/Financial Services

- Beverages/Foods/Nutritional Products

- Boat and Marine

- Cannabis and Medical Marijuana

- Construction/Building Trades

- Consumer Electronics

- Consumer Products

- Digital Currency/Cryptocurrency

- Drones/UAVs

- E-Cigarette & Vaping Technology

- E-Commerce

- Education & Training

- Energy/Power Generation

- Health and Beauty Products (HBP)

- Human Resources

- IoT Patents/Internet of Things

- Manufacturing

- Medical Electronics and Devices

- Mining/Drilling

- Mobile/Wireless

- Network/Location-Based Services

- Optics/Displays/Video/LED

- OTT Patents/Over-the-Top

- Packaging

- PCs and Notebooks

- Pharmaceuticals

- Robotics/Automation

- Semiconductor

- Shoe & Apparel

- Smart Home/Smart Office

- Social Media

- Software, Apps, and Architecture

- Sports/Sporting Goods

- Telecommunications/IP Telephony

- Warehousing/Material Handling

- Other

- Go to Patent Index

- Return to Patent MarketPlace