Patent MarketPlace: Construction Patents and Building Trades Technology Patents for Sale

Welding Torch with Stereoscopic Camera (Mudd): U.S. Patent No. 12,323,572

Welding Torch with Stereoscopic Camera (Mudd): U.S. Patent No. 12,323,572

The world we live in today would not exist without welding. We would not have cars, trucks, busses, or trains without welding. No office buildings or warehouses or factories. No refineries. No power plants. A serious challenge facing welders – especially when they are making repairs – is getting to the area that needs welding. A pipe that needs to be welded is often inside a wall, or below a floor, or in a cavity that the welder cannot see into. In a refinery, as just one example, a pipe that needs to be repaired may be blocked by other pipes that may have to be cut away to gain access to the pipe that needs to be welded. Some welders have to resort to using mirrors to see where they are welding!

This patent mounts a stereoscopic camera on the end of a welding stinger enabling the welder to see what he (or she) needs to see on a video display mounted in his helmet. The welder does NOT have to be directly over the spot he is fixing. This patented configuration enables a welder to work on anything he can reach, even if it is out of his line of sight. No more cutting pipes or using mirrors. This device enables the welder to see the melted puddle, which is critical!

U.S. Patent No. 12,323,572 for a “Stereoscopic camera system for a welding torch” would enable any welding supplies manufacturer to offer its customer visual access to work areas they could not otherwise see.

Leak-Proof Flange Joining Structure (Kyowa): U.S. Patent No. 10,145,498

Leak-Proof Flange Joining Structure (Kyowa): U.S. Patent No. 10,145,498

Water main breaks are a common sight these days. As the infrastructure ages, and the traffic over buried water lines increases, vibration, weight, and time eventually cause the connections between pipes to fail. We see the same problem in older building where pipe lines burst after years of vibration from HVAC, elevators, floor traffic, remodeling, and the expansion and contraction caused by changes in the weather.

This patent relates to a next-generation flange gasket used in flange joints. It features a stainless-steel plate core with a corrugated (uneven) surface that is rubber-lined. The rubber lining has a dual-ring structure on its surface, and the corrugation ensures that only the ring portions are uniformly compressed, providing a reliable water-sealing effect. This structure prevents the gasket from rupturing under pressure fluctuations such as water hammer, and allows for a stable and consistent connection between the flange and the gasket regardless of worker skill level or variations in bolt-tightening torque, thereby creating a 100% water-tight seal. Not only does this next-generation flange gasket create a water-tight connection, it is impervious to the vibrations – traffic, elevators, escalators, HVAC, construction, and the weather (even earthquakes) – that cause other flange connections to fail.

U.S. Patent No. 10,145,498 for a “Flange joining structure and seal body used therein” would enable any piping manufacturer to introduce to its customer base – and the customers of all of its competitors – a next-generation flange connection that is fail-safe!

Go Anywhere, Use Anywhere Portable Vise (Emmert): U.S. Patent No. 12,151,340

Go Anywhere, Use Anywhere Portable Vise (Emmert): U.S. Patent No. 12,151,340

The bench vise that is in common use today actually goes back to 1750, although the original inventor apparently failed to file a patent for it. For nearly 300 years, vises have been high-demand tools in workshops and fabrication facilities. They are durable, affordable, reliable, easy-to-use, and multi-functional. Holding a pipe so it can be cut or threaded; securing a piece of wood so it can be sawed, drilled, or sanded; and holding two glued pieces together until the glue sets are just a few of the bench vise’s many applications. No workshop can operate without a bench vise.

But what about when you are NOT in the shop? What about repairs that have to be made on-site? What about electrical, carpentry, or plumbing that is done at construction sites or at businesses or residential projects? This patent solves that need. It creates a portable bench vise that can be clamped to any flat surface in any location and used just like the bench vise back at your workshop. It can then be unclamped and ported to the next location.

Unlike other portable vises, this patented vise can be clamped to a pickup truck tailgate turning the tailgate into a bench surface for tools, parts, and other workpieces that is at the right height to avoid bending and back pain. The distance between the clamping jaws on each side can be independently adjusted to offer different clamping lengths. With one vise jaw secured to its internal structure and the other jaw rotatable, workpieces with non-parallel surfaces may be easily vised. As a bonus feature, both vise jaws can be extended and secured at a position out beyond the edge of the bench or tailgate, providing more vertical distance to the floor or ground enabling work on pieces of any size. Being clamped to a very stable bench or tailgate, long lumber or other materials can be vised without tipping over – a problem with some other portable vises.

U.S. Patent No. 12,151,340 for a “Portable utility vise device” will enable any bench vise manufacturer to add a new product category to its product line-up.

Placement and Retrieval of Construction Cones (Hayes): U.S. Patent No. 12,240,710

Placement and Retrieval of Construction Cones (Hayes): U.S. Patent No. 12,240,710

Those orange traffic cones and barrels (they are officially “traffic delineators”) are a common site these days. As our infrastructure ages, highway construction projects proliferate across the country. And to perform highway repairs, paving, and upgrades, a worker has to walk alongside a flatbed truck in traffic and place cones or barrels on the highway to redirect the traffic around the construction. And when the job is done, he has to walk alongside a flatbed truck in traffic and retrieve those cones or barrels. The process of manually distributing and retrieving these cones is not just labor-intensive, it is dangerous. Hundreds of highway construction workers lose their lives each year in the U.S. at highway construction sites.

This patent automates the process of distributing and retrieving construction cones and barrels. It creates a device that sits on the back of a flatbed truck or trailer. An arm swings around, grabs the traffic delineator, and drops it onto the roadway. A programmable one-arm controller defines how often a delineator will be dropped based on the speed of the truck. When the construction is completed, the apparatus reverses the process, swinging out and grabbing the cone or barrel and then swinging back and placing it back onto the flatbed. This device saves labor costs and totally eliminates injuries and deaths among the workers who did this manually.

U.S. Patent No. 12,240,710 for an “Apparatus and method for handling portable traffic delineators” would be an excellent acquisition for any manufacturer of highway construction tools and equipment.

Next-Generation Pick-Proof Lock (Pierce): U.S. Patent No. 12,188,259 and Application 20250137291

Next-Generation Pick-Proof Lock (Pierce): U.S. Patent No. 12,188,259 and Application 20250137291

The pin-and-tumbler lock has been around for hundreds of years. It is also known as the "Yale" lock as they are named after Linus Yale who received U.S. Patent No. 32331 in 1861 for a “Lock.” Yale’s basic design has persevered, and the locks of today are not very different from Yale’s original concept. Many of the latest generation of electronic locks still use the same pin-and-tumbler concept, they just lock and unlock electronically – even remotely. The problem is that it is relatively easy to pick a pin-and-tumbler lock regardless of who locked it or how it was locked! Worse still, many are vulnerable to unskilled manipulation attacks such as bumping or raking.

This patent and continuation create the first fundamental advancements in locks since the Civil War! The lock covered by this patent family uses a key like conventional locks. The lock design uses a partial rotation of the core to separate key-configured driver pins from the keyway before comparing the driver pins against a reference element, which blocks or allows further rotation depending on their configuration. This core rotation separates the input of key bitting at the keyway from verification of that information internally, making all manipulation attacks impossible as the status of each driver pin is not transmitted back to the key pins. Locks based on this patent family would be about the same size as current pin-and- tumbler locks, and about the same cost to manufacturer, so current easy-to-pick locks could easily and affordably be replaced with impossible-to-pick locks!

U.S. Patent No. 12,188,259 and Application 20250137291 for a “Lock, methods of using and making, products, and necessary intermediates” would enable any lock manufacturer to leapfrog the technology of all of its competitors and be able introduce a next-generation, pick-proof lock!

Highly Effective Burglary Deterrence (Priyasun): U.S. Patent Application 20250179871

Highly Effective Burglary Deterrence (Priyasun): U.S. Patent Application 20250179871

It is a sad reality of the current times that burglaries are all-too common. The only good news is that burglars are very fair – they rob from both the rich and the poor. Any business owner that locks up at night does not really go home secure that his or her business is safe. Burglars break in, the alarm goes off, but they are gone with the goods before the police show up, and even if they are caught on the video security cameras, they are rarely caught or punished. In fact, many return to burglarize the same business.

This patent creates both an end to burglaries and captures the thief in the process! It consists of a collapsible grill assembly that drops down from the ceiling, stopping the burglar in his (or her) tracks and capturing the thief at the same time. A burglar breaks open a locked door and enters your building. The system detects any attempt to steal anything with calibrated force and it automatically drops down a grill assembly that traps the thief in a hallway or foyer. He is not injured – just very frustrated! Your alarm goes off, but regardless of when the police arrive, the red-handed thief is waiting for them. Here is technology that (1.) stops thieves in their tracks, (2.) prevents thieves from stealing anything, (3.) captures the thief, and (4.) sends a message to every other thief or wanna-be thief in the neighborhood what the worst business in town to try to break into is! The technology even works during power outages or should the burglar cut off power to the building. This patent offers a high level of security at relatively low cost.

U.S. Patent Application 20250179871 for a “Burglar trapping system” would enable any manufacturer of security systems to offer the ultimate solution to burglaries!

Post Support and Leveler (Radhs): U.S. Patent No. 12,044,025

Post Support and Leveler (Radhs): U.S. Patent No. 12,044,025

When constructing a fence or other structure that requires that posts be planted in the ground, it is a common practice to dig a hole, place a post into the hole, and then fill the hole with concrete. Once the concrete hardens, the post is securely in the ground. This is then repeated for every post. While this system is labor-intensive, it is a common practice that has been around for a few hundred years. It is clearly a two-man job, as one worker must hold the post in a plumb position while the second worker pours the concrete into the hole. And the first worker must continue to hold the fence post in a vertical position until the concrete begins to set and harden. If he lets the post move out of plumb, and lets the concrete harden, that post and its concrete base will have to be dug out of the ground and new post will need to be installed. All the posts must be perfectly vertical for the structure to be right. Some contractors nail diagonal supports to the posts to keep them vertical while they wait for the concrete to harden, requiring yet more labor to get the job done. There must be a way to reduce the labor required to set posts in the ground for fences, signs, light poles, porches, decks, stoops, mailboxes, pergolas, gazebos, and other structures.

There is. This patent creates a tool that holds the post in a perfectly plumb position. It has a collar that slips over the post, and clamps that hold the collar in place. It has four adjustable legs that extend down to the ground. Once the device is placed on a post, it can be adjusted to hold the post perfectly vertical in a matter of seconds. No worker is needed to hold the post plumb. The concrete is poured into the hole, and the worker then proceeds to the next hole. A homeowner might use just one support tool and move it from post to post, while a contractor would likely use multiple supports so several posts can be kept vertical at the same time. A tool based on this patent is easy to manufacturer and offers a practical and affordable solution to the more efficient and more cost-effective setting of posts in concrete.

U.S. Patent No. 12,044,025 for a “Ground post support and level device” would enable any manufacturer of construction tools to introduce and own a new product segment.

Capture and Re-Cycling of Cutting Fluid (Buchholtz): U.S. Patent No. 12,097,584

Capture and Re-Cycling of Cutting Fluid (Buchholtz): U.S. Patent No. 12,097,584

It is a common practice to spray or flood cutting fluid onto metals parts that are being cut, ground, machined, lathed, or shaped on CNC machinery. This fluid is costly, yet it is typically discarded along with the chips rather than being recycled. This patent creates a device to fill that void.

The patent creates a tray that collects the discarded cutting fluid from a metalworking chip conveyor. The tray has a slanted surface so the swarf (metal debris) is separated from the cutting fluid while the cutting fluid is directed to a fluid reservoir so it can be returned directly back to the machine. The device is a quick add-on to any style chip conveyor and has no moving parts. The savings in cutting fluid – that would otherwise be disposed of – pays for the device in a matter of a few months to a couple of weeks! This invention significantly reduces coolant and disposal costs, which are constantly increasing, and it enables a manufacturer to stay current with OSHA waste-fluid disposal regulations.

U.S. Patent No. 12,097,584 for a “Cutting fluid catch mechanism” would enable any supplier of manufacturing equipment to offer a money-saving product for its customer base.

Lightweight Structural Alternative to Steel and Concrete (Startlink): International Patent Portfolio

Lightweight Structural Alternative to Steel and Concrete (Startlink): International Patent Portfolio

Steel and concrete are the materials of choice when it comes to the construction of commercial and industrial buildings like offices, factories, and warehouses, despite the fact that steel and concrete are significant contributors to global CO2 levels. No other material has been able to compete with steel for over 150 years – until now.

This portfolio creates an entirely new concept in columns, trusses, and gantries for all types of construction. It uses a composite alternative that is as strong as steel but 40% of the weight. It will not rust or rot. It reduces CO2 emissions by 80% and costs less than steel! It joins hollow rectangular sections made by pultrusion without using metal or adhesive. Instead, it uses threaded fibreglass rods and glass-filled nylon nuts that have been tested to 80 kilonewtons. They connect pultruded box profiles to make columns, trusses, and gantries that are as strong and stiff as steel, but are much lighter and cheaper to produce. They need no maintenance. They can replace concrete foundations and unlike steel, will resist corrosion by seawater. At end of life, they can be dismantled and recycled so nothing goes into the landfill. Based on this patented technology, a 5m truss weighing 35kg was tested by Coventry University and it supported a central load of 2½ metric tons without failure!

International Patent Portfolio

- U.S. Patent No. 10,612,240: Fibre reinforced polymer structures

- European Patent 3356614: Fibre reinforced polymer structures

- Canada Patent 299994: Fibre reinforced polymer structures

- Australia Patent 2016332619: Fibre reinforced polymer structures

- India Patent 459613: Fibre reinforced polymer structures

- UK Patent 2542816: Fibre reinforced polymer structures

This portfolio can be used by a supplier of construction materials to introduce the first serious competitor for steel since it was invented over 1,000 years ago!

Concrete Floor Construction Tool (York): U.S. Patent No. 9,463,961

Concrete Floor Construction Tool (York): U.S. Patent No. 9,463,961

High-rise steel-and-concrete buildings are constructed floor by floor. The floor for each level is poured in place as one monolithic concrete slab. Formworks for large floor sections are built on the ground. The formwork for the entire floor section is then lifted into the air by a crane and “flown” into position at the highest floor of the building. Once in place, concrete is poured into the form to create the floor structure. After the concrete has cured, the forms are then extracted and flown into place for the next floor and filled with concrete again, so on and so on for the entire building. This whole-floor framework is referred to as a “deck” or “table” and the process is known as “flying-deck” construction. Lifting up each concrete slab form table is a dangerous, precarious, and time-consuming task.

The invention covered by this patent is called a “Compensator” and it features a spreader bar that is attached to a crane rigging to improve the process of moving concrete deck forms in flying-deck construction. The invention covered by this patent has been used, safely and effectively in high-rise building construction projects to over 70 stories in height. The Compensator has not to date been the cause of any job site interruption or job site downtime since the product came to market in 2007. In addition to the patent, copyrighted crane and rigging crew signaling handbooks, power point training and educational, safety programs, and other useful intelligence and know-how are available so the acquirer of this portfolio can go to market with product very quickly!

U.S. Patent No. 9,463,961 for a “Compensator system and method for moving construction form tables” would enable any manufacturer of construction equipment to offer its customers a tool that will save time and reduce costs in flying-deck construction. The inventor did the design and engineering work necessary to bring a product to market and that know-how is also available.

Next-Generation Electrical Outlets and Switches (Blurton): U.S. Patent No. 7,744,407

Next-Generation Electrical Outlets and Switches (Blurton): U.S. Patent No. 7,744,407

Not much has changed in the electrical switches and outlets we use every day in our homes, businesses, schools, and other facilities. A few years ago, the ground fault circuit interrupter (GFCI) outlet was introduced. It protects users from electrocution by cutting off power if there is a surge in amperage. Other than the GFCI outlet, electrical switches and outlets have remained unchanged for decades and are connected by 12 or 14-gauge electrical wire that an electrician fishes through the wall and into the electrical circuit box. The wires are then stripped and a hook is made so the wires can be attached to screws on the side of the switch or outlet, then tightened down with a screw driver – an highly labor-intensive process.

This patent is the first significant improvement to electric switches and outlets in a century! Under this patented design, power cables run through the electrical circuit box – rather than having to be fished into the boxes and then connected to the switch or outlet – and the light switch or electrical outlet is plugged directly into the circuit box! It is the hard-wired equivalent of “plug and play.” Labor is dramatically reduced since the electrician no longer has to manually connect the live, negative, and ground wires to each and every switch and receptable. And replacing a switch or outlet is like changing a light bulb! This patented design totally eliminates the common problem of attaching wires to a switch or outlet only to have one of the wires pop off when the switch or outlet and all the excess wiring is pushed back into the circuit box.

U.S. Patent No. 7,744,407 for “Modular circuit boxes and associated components” will enable any manufacturer of circuit boxes, light switches, and electrical outlets to offer an entirely new generation of products for wiring homes, businesses, factories, schools, and other facilities!

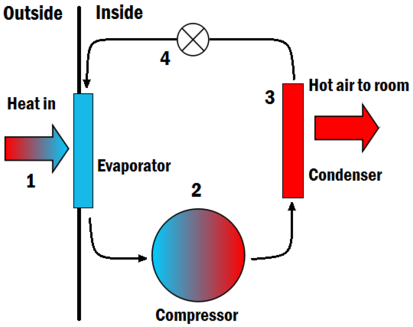

AC Heat Capture and Re-Use (Sheneman): U.S. Patent No. 11,952,961

AC Heat Capture and Re-Use (Sheneman): U.S. Patent No. 11,952,961

Most people do not realize that traditional air conditioning units – while cooling our homes and businesses – also generate a lot of wasted heat. This heat is typically discharged into the atmosphere, requiring an outside unit for the AC system to release this heat. What if we could eliminate the need for an outside unit and instead capture that heat for more productive use?

This patent covers groundbreaking technology that captures the heat generated by an air conditioning system and converts it into energy. This energy is then cycled back into the system, effectively powering the energy pump itself. The result is no need for an outside unit to expel heat. Instead, the system becomes self-sustaining, harnessing the energy it produces for continuous operation. This innovation has the potential to revolutionize the HVAC industry. By converting waste heat into usable energy, it eliminates the inefficiencies of traditional AC systems. Air conditioning manufacturers that adopt this technology will not only be able to offer more compact and environmentally friendly systems, but also ones that reduce energy consumption and operating costs. Imagine an air conditioning system that doesn’t just cool your space but also powers itself through the very heat it generates.

U.S. Patent No. 11,952,961 for an “Energy pump” opens the door to a new era in energy-efficient cooling without the need for bulky outside units and with the added benefit of capturing and reusing energy that would otherwise be wasted. The possibilities for its application are endless, and any company that adopts this technology will be at the forefront of the next generation of HVAC innovation. This company that acquires this patent will leapfrog the technology of all of its competitors and offer cutting-edge benefits are both cost-effective and eco-friendly.

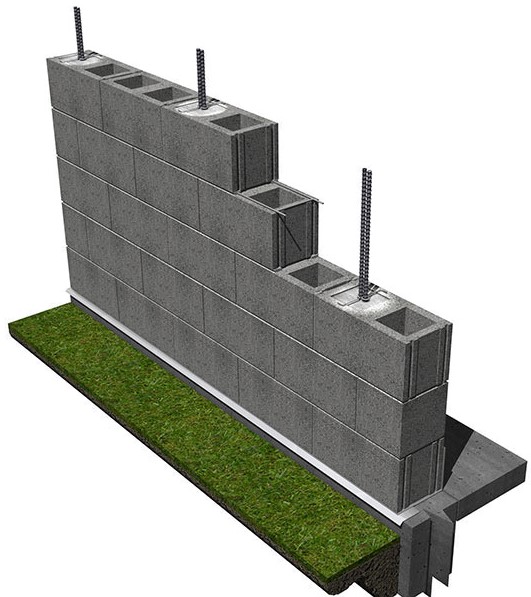

Grout Consolidator for Reinforced Concrete Masonry (Baker): U.S. Patent Nos. 8,092,071 and 8,353,618

Grout Consolidator for Reinforced Concrete Masonry (Baker): U.S. Patent Nos. 8,092,071 and 8,353,618

When concrete is poured, it is critical to remove all pockets of air to insure the strength and integrity of the concrete. And there are tools specifically designed to remove any air pockets from freshly poured concrete. When a wall is constructed from concrete masonry blocks, grout, and reinforcing bars (or “rebar”), it is equally important that the grout be consolidated—that is, all air pockets must be removed from the grout to insure the strength and integrity of the masonry wall assembly. But there are currently no tools to do that. Until now.

This patent family creates a tool that efficiently consolidates grout in concrete masonry and Insulated Concrete Form (ICF) construction. It includes a vibratory clamp that attaches to a reinforcing bar while the rebar is sitting in still fluid grout inside the masonry blocks or ICF units during grouting operations. The tool vibrates the reinforcing bar, and that vibratory energy brings up any air pockets in the grout, resulting in a solid and consistent fill of grout between the rebar and the blocks, thus insuring a code-compliant wall with the intended design strength and integrity.

U.S. Patent Nos. 8,092,071 and 8,353,618 for an “External vibratory grout consolidator for vertically reinforced concrete masonry” would enable any manufacturer of masonry and concrete tools to introduce a new product that meets a real need in masonry or ICF construction.

Cement Mixer Truck Chute Cleaner (Hassan): U.S. Patent No. 11,794,225

Cement Mixer Truck Chute Cleaner (Hassan): U.S. Patent No. 11,794,225

Cement and concrete are everywhere – buildings, bridges, highways, parks, swimming pools, and dams to name just a few. Cement is a binding agent used to hold bricks and stones together, while concrete contains rock (or “aggregate”) and is poured into forms to create walls and floors. Cement and concrete are created by mixing together the ingredients and loading the mixture into a cement mixer truck. The truck then delivers the liquid mixture to the job site, and the liquid concrete is emptied from the truck via a series of chutes and extensions.

Once the wet concrete has been off-loaded from the truck, there is the problem of cleaning the chutes and extensions that delivered the wet mixture. The wet concrete begins to dry and harden immediately. Washing out the chutes and extensions with water removes just some of the hardening concrete. What is needed is a tool that is specifically designed to quickly, efficiently, and thoroughly remove ALL of the wet mixture before it hardens. This patent creates just such a tool. The scraper covered by this patent is a manually controlled tool that uses bi-directional scraping to remove cement regardless of its hardness. It conforms to the exact inner diameter of the chutes and extensions, so it completely removes the mixture before it hardens. Braided steel wires on the perimeter of the tool create abrasion that scrapes any dried cement or concrete from the chutes and extensions. This tool replaces having to use harsh chemicals to clean the chutes and extensions on cement mixer trucks.

U.S. Patent No. 11,794,225 for a “Radius scraper” would enable any supplier to the construction industry to offer its customers a tool that will reduce their labor costs, increase productivity, and minimize the use of harmful chemicals to clean the chutes and extensions on their cement mixer trucks.

Also available from this inventor is U.S. Patent D1024140 for a “Concrete funnel".

Lateral Stepstool and Work Platform (Hixson): U.S. Patent No. 11,825,942

Lateral Stepstool and Work Platform (Hixson): U.S. Patent No. 11,825,942

We’ve all be there. We are painting, spackling, stripping or hanging wallpaper, or hanging a picture using a stepladder or stepstool. While the stepladder or stepstool enables us to reach the top portion of the wall, it limits horizontal access, so we need to climb down, move the stepladder, climb back up, do some work, climb back down, move the stepladder, climb back up – you get the idea. Yes, we could construct a work platform or scaffold, but that would just be more work and time and expense. Isn’t there an easier way to spackle, or paint, or strip and hang wallpaper, or do other work around the house? Or detail a car or truck?

There is. This patent creates what is essentially a lateral step stool that replaces the traditional stepladder or stepstool. Rather than being just 14 or 20 inches wide – which means it must be constantly moved as you work your way across the room – it can be manufacturer to seven or eight feet wide. It has fold-out legs that support two horizontal surfaces – like the first and second steps of a stepladder. The lower section is in front, so you step onto the lower horizontal surface first, then step onto the higher horizontal surface to reach your work area. This practical work platform can be much wider than a conventional stepladder or stepstool based on the strength of the material used to construct it. You start at one end of the top step and work across as you spackle, or paint, or do whatever you are doing. You save all those trips up and down a conventional stepladder and you eliminate all those moves of the stepstool as you work your way across the wall. Less climbing up and down will result in less fatigue, improved productivity, and a safer work environment. In fact, you could have two workers on the device to really improve productivity! When it is not needed, it folds up for easy storage and transport to the next work site.

U.S. Patent No. 11,825,942 for a “Collapsible platform assembly” would enable any stepstool/stepladder manufacturer to introduce and own a new market segment in the home improvement sector!

Improved Insulator Cleaning System (Zbinden): U.S. Patent Nos. 11,148,174 and 11,358,181

Improved Insulator Cleaning System (Zbinden): U.S. Patent Nos. 11,148,174 and 11,358,181

In addition to generating electricity and delivering it to its customers, electric utilities have a huge infrastructure to maintain. One of the many challenges facing electric utilities is keeping all those insulators clean. Insulators prevent current from the power or distribution line from going into the utility pole and ultimately into the ground. The dirt, dust, grime, and other debris that collects on insulators can create a path for the electrical current to bypass the insulator and escape into the ground, resulting in a serious loss of deliverable electrical current for the utility.

This patent family addresses the challenge of keeping insulators clean by creating a device that scrubs both the outside of the insulator and the surface between the insulator disks. A utility worker standing on the ground uses the device to remove dirt, dust, grime, and anything else that has collected on the insulator. A sponge and flexible rubber blade both insulate the worker and remove any foreign material from the insulator. The tool has threaded attachments that adjust it to the desired length. The tool created by this patent can be used to clean insulators at substations as well as on distribution and power lines.

U.S. Patent No. 11,148,174 for an “Electrical insulator manual cleaning device” and U.S. Patent No. 11,358,181 for an “Extendable cleaning device for electrical insulators” would enable any manufacturer of tools for the electric utility industry to offer its customers a next-generation solution to cleaning their insulators.

Utility Pole Removal and Inspection Auger (Falkenhagen): International Patent Portfolio

Utility Pole Removal and Inspection Auger (Falkenhagen): International Patent Portfolio

One of the most common sites around the world today are utility poles. They dot the landscape as they carry electricity, telephone service, and cable content to homes and businesses. There are 180 million utility poles in the U.S., over 500 million in China. With an average life of just 30 to 40 years, the utility that owns and maintains this important infrastructure item is always removing old poles and replacing them with new. And then there are all the road-widening projects that require utility poles to be uprooted and replaced with new ones farther into the right-of-way. On top of this, utility poles need to be periodically inspected.

Utility poles are currently removed by digging with shovels around the perimeter of the pole until it is loose enough that the pole can be lifted up and out of the ground. The current method is back-breaking, labor-intensive, time-consuming, and not very efficient. This international portfolio creates a tool that quickly, efficiently, and economically removes utility poles. It attaches to the perimeter of the pole and a threaded sleeve drills down and removes the soil and rock from around the buried portion of the utility pole about 10 inches out so it can be easily lifted up and carted away. The whole process takes just a few minutes!

This auger created by this portfolio also has applications for the utility pole inspections that are mandatory in most countries. In the U.S., for example, utility poles must be inspected every seven years. The auger provides inspection depth two feet down. By replacing having to remove dirt from around the utility pole by shovel, this tool dramatically increases productivity! This patented tool can excavate approximately 160 poles in an eight -hour shift compared to just 20 poles when they have to be dug out with a shovel.

Patent Portfolio

- U.S. Patent No. 11,866,906: Hollow boring auger

- China Patent Application 107614826: Hollow hole twist bit

- European Patent 3277908 3277908: Hollow boring auger

- Japan Patent Application 2018509548: Hollow boring auger

- Australia Patent 2016240396 2016240396: Hollow boring auger

This portfolio will enable any supplier of tools to the utility industry to offer a time-saving, money-saving solution to removing and inspecting utility poles.

Extremely Durable, Non-Combustible Building Panels (Dopp): U.S. Patent No. 11,560,716

Extremely Durable, Non-Combustible Building Panels (Dopp): U.S. Patent No. 11,560,716

There are areas of the country – such as California – where a house being destroyed by a forest fire is a not an unusual event. And when a forest fire gets out of control – as they so often do – and burn down hundreds or thousands of homes, all those structures are totally losses that have to be completely rebuilt from the ground up. As an added tragedy, the contents of the destroyed homes – including irreplaceable items like family photos and mementos – are lost forever! Surely there must be a solution.

There is. This patent introduces technology for floor, wall, and roof panels that are not just fire-resistant, they are non-combustible! Built with steel frames and cementitious sheathing, these construction panels are lightweight and durable, and will withstand a forest fire. Since the exterior of the house is non-flammable, the fire will pass by the house for lack of fuel, saving not just the house from total destruction, but also protecting the contents of the house. Other than smoke damage, a building constructed with these patented panels will withstand any forest fire with NO substantial damage to the structure or its contents!

To build a structure using this technology, the architectural plans are submitted to the manufacturer, and CAD software configures the dimensions of the panels that will be needed. The panels are manufactured, shipped to the construction site, lifted into place, and bolted together. The doors and windows, plumbing and wiring, duct work, and fixtures are then installed just as they would be in a conventionally constructed house. U.S. Patent No. 11,560,716 for “Methods and apparatuses for facilitating producing of an insulated panel” will enable any housing materials manufacturer to introduce the next generation in modular housing components.

Faster, Cheaper Manhole Construction (Gilbert): U.S. Patent No. 10,458,093

Faster, Cheaper Manhole Construction (Gilbert): U.S. Patent No. 10,458,093

Manholes are a common site across America. We ride over them and walk over them – or around them – without giving them much thought. Manholes provide access to the unseen underground infrastructure that makes life in the modern world possible. Clean drinking water, electrical power, sewage and waste removal, natural gas, telephone and Internet, and many other services are accessed from manholes. However, constructing a manhole has been an expensive and time-consuming process that includes fabricating a form, filling it with poured concrete, waiting for the concrete to harden and cure, and then detaching and removing the form and transporting one of the heaviest products imaginable to its next location. That has been the process…until now.

This patent dramatically simplifies the process, providing technology that saves time and material costs. The patented system uses a two barrel pre-fabricated mold that is made from common plastic materials. The inner and outer barrels are welded in place to secure them and the cavity between them is filled with concrete. When the concrete hardens, it creates a ready-to-use manhole. The manhole can be constructed in-place on-site or off-site and then transported and dropped into place. The form system becomes a permanent integrated feature of the finished manhole. This patent does not create a new type of manhole, but addresses a more cost effective and faster way to construct manholes.

U.S. Patent No. 10,458,093 for an “On-site manhole casting system” would enable any supplier of construction materials to offer its customers a device for fabricating manholes faster and cheaper than the current process.

Footless Concrete Foundations (ISBP): U.S. Patent No. 8,516,773

Concrete foundations for buildings have not changed much over the last 100 years. A process of formwork, pouring, and stripping is done twice – first for the footings and then, after they have cured, once again for the actual foundation walls. While this system does work, it is expensive, labor-intensive, and time-intensive.

This patent takes the pouring of foundations to a new level by eliminating separate footings. Conventional forms are used in a patented method that provides both the footing and foundation walls in one pour instead of two. And it does this using the same amount of concrete as is used in the slower two-part process. This new technology reduces construction time, saving an average of two days in the schedule. It also saves significantly on the basement slab since the pad is prepared only once for both the foundation and the slab – no coming back to fill, grade, and compact for the slab. And excavation cost are less, saving over 100 yards of removal and later fill.

U.S. Patent No. 8,516,773 for a “Foot free concrete foundation method and device” would be a valuable acquisition for any building supplies manufacturer that is ready to leapfrog the current technology and offer serious savings to contractors that are building concrete foundations.

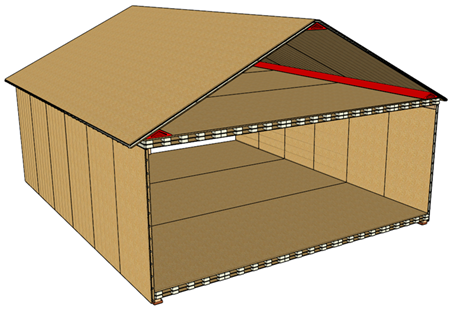

Frameless Construction (ISBP): Nine U.S. Patents and Application Portfolio

Frameless Construction (ISBP): Nine U.S. Patents and Application Portfolio

Residential construction methods have not changed much over the years. The same joists, studs, trusses, and rafters have been used to build everything from houses to schools, hotels, and offices for centuries. In fact, the only major innovations were plywood/Oriented Strand Board and gypsum board, but they are both nailed to the same joist-stud-rafter frame. Current home construction is labor-intensive, highly inefficient, and far too expensive!

This portfolio changes all that by creating a frameless construction system in which 4 x 8-foot or longer panels are connected to form floors, walls, and roofs. The panels leave space that allows air to circulate – keeping the structure cool in the summer and warm in the winter – and accommodates plumbing and wiring. Holes are cut for windows and doors. These ventilated plenum panels are delivered to the construction site just as plywood or gypsum board would be, but NO joists, studs, trusses, or rafters are delivered as they are not needed. The panels are lifted into place and connected to each other to form a tight, solid, integral structure at less cost and in less time than convention “stick” construction!

Patent Portfolio

- U.S. Patent No. 8,490,355: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 8,534,018: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 8,615,945: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 8,635,822: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 9,050,766: Variations and methods of producing ventilated structural panels

- U.S. Patent No. 9,091,049: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 9,604,428: Ventilated structural panels and method of construction with ventilated structural panels

- U.S. Patent No. 10,822,790: Frameless construction using single and double plenum panels

- U.S. Patent No. 11,492,796: Frameless construction using single and double plenum panels

The acquirer of this portfolio will be able to offer a totally new, patent-protected, concept in construction that will dramatically reduce both labor and material costs, resulting in faster construction of buildings at less cost!

Mobile Tool Cart and Workbench (Mobile Designs): U.S. Patent No. 9,849,582

Mobile Tool Cart and Workbench (Mobile Designs): U.S. Patent No. 9,849,582

Performing any type of carpentry or other tradecraft work at a construction site usually requires lifting and transporting heavy power tools from a truck to the workplace and back to the truck. In many cases, this work is performed by a single worker without help. Moving tools and construction materials to the job site and back to the truck wastes time and is not productive. Lifting heavy loads exposes workers to injuries that add to the cost of the project. On site, the power tools must be mounted to a saw table that may not be sturdy, nor the ideal height, nor may provide proper support. These conditions compromise workplace safety and reduce productivity. Not good. Not smart. Not efficient.

The ideal solution would be sturdy mobile steel cart that can be moved in and out of a truck bed with a load of up to 350 pounds of tools on it without the worker having to lift all that weight. It would have fold-down legs like an ambulance gurney, it would incorporate a wood top for mounting power tools, and it would provide a flat working surface at the job site. It would have adjustable legs compatible with most truck bed heights, and its legs would have wheels that can be tailored to the job site terrain. At the end of the workday, it could be rolled back to the truck and slid into the cargo bay.

That is exactly the invention covered by this patent! U.S. Patent No. 9,849,582 for a “Rollaway storage cart with collapsible legs” creates exactly the perfect cart and workbench for any construction site. The inventor of the patent has manufactured prototypes already in use on job sites today. The invention would enable any seller or manufacturer of construction equipment or power tools to introduce a new product that saves time and improves workplace safety. The "video" link below shows a version of this invention, the “Work Sherpa,” in use.

Patent Brokerage Prospectus: Contact [email protected] to receive an analysis of each portfolio that includes:

- Executive Summary

- Patent Overview and History

- Technology and Investment Summary

- Market Research

- Company Analysis

- Illustrative Evidence of Use (if applicable)

We offer patents in these technologies:

- Agricultural

- Artificial Intelligence

- Automotive/Vehicular

- Aviation

- Banking/Financial Services

- Beverages/Foods/Nutritional Products

- Boat and Marine

- Cannabis and Medical Marijuana

- Construction/Building Trades

- Consumer Electronics

- Consumer Products

- Digital Currency/Cryptocurrency

- Drones/UAVs

- E-Cigarette & Vaping Technology

- E-Commerce

- Education & Training

- Energy/Power Generation

- Health and Beauty Products (HBP)

- Human Resources

- IoT Patents/Internet of Things

- Manufacturing

- Medical Electronics and Devices

- Mining/Drilling

- Mobile/Wireless

- Network/Location-Based Services

- Optics/Displays/Video/LED

- OTT Patents/Over-the-Top

- Packaging

- PCs and Notebooks

- Pharmaceuticals

- Robotics/Automation

- Semiconductor

- Shoe & Apparel

- Smart Home/Smart Office

- Social Media

- Software, Apps, and Architecture

- Sports/Sporting Goods

- Telecommunications/IP Telephony

- Warehousing/Material Handling

- Other

- Go to Patent Index

- Return to Patent MarketPlace